simonjackson1964

Mitglieder

-

Benutzer seit

-

Letzter Besuch

Alle erstellten Inhalte von simonjackson1964

-

Program the rotation of a person on a virtual track

Now can you get him to put the package down, ring the doorbell and take a photo with his phone...?

-

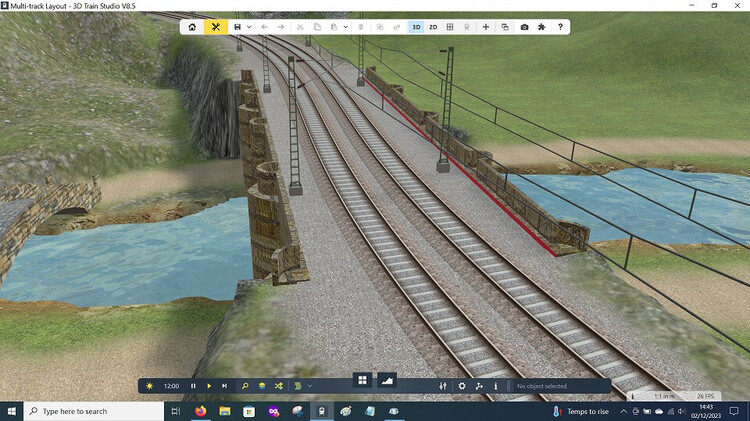

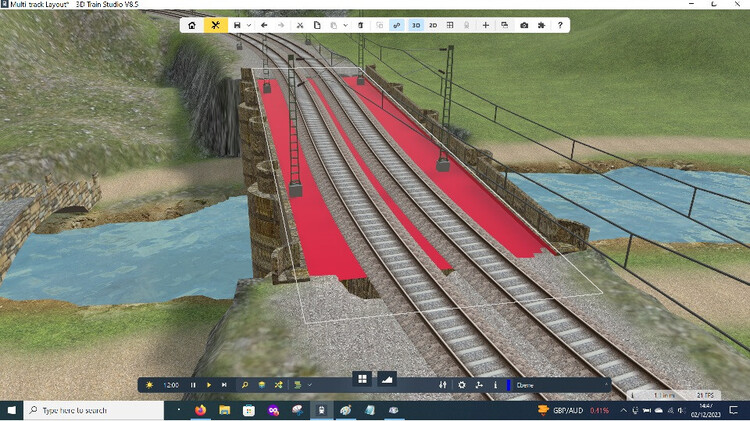

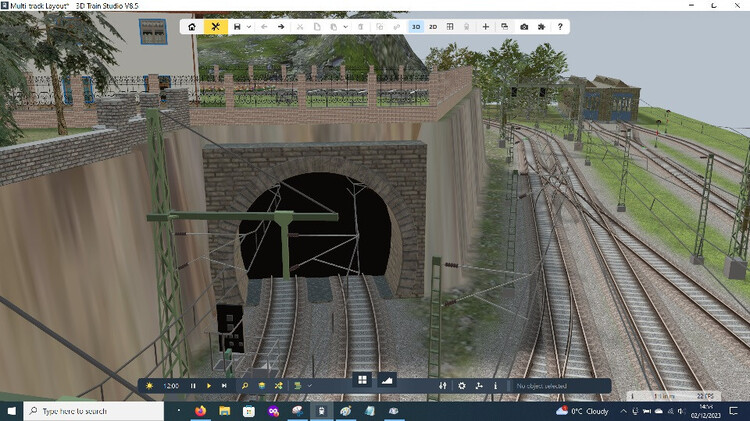

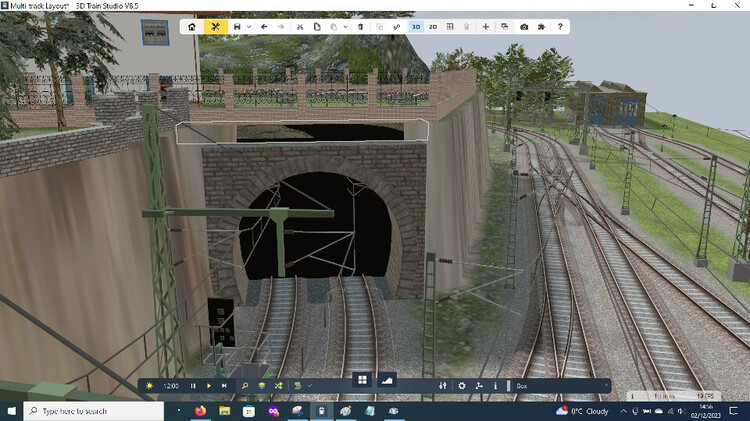

Using Primitives to fill in holes.

This isn't a problem so much as a solution to one, that I thought I'd share, in case any newer members are having the same trouble and haven't come up with their own way of solving it yet... So the problem arises because the baseboard is based around a rectangular grid. Obviously this has to be there, and frankly I'm always amazed at the level of detail the graphics in MBS can display. But the simple fact is that the rectangular grid creates corners And when raising or lowering terrain to create bridges or tunnels, these corners can get in the way. This is especially the case when creating embankments or cuttings using the ramp tool, and the track is not angled exactly at 0°, 90°, -90° or 180°. When trying to put a bridge on that track, one can find that the baseboard pokes through the support piers. Move the bridge away or lower the offending bit of terrain so it doesn't, and you end up with gaps... Now, if you aren't a perfectionist like me then, this may be acceptable to you. Each to their own, as I've stated in a different thread on this forum. Some people just want to get everything moving and aren't bothered by what it looks like... Others, like me, want everything to look right. And of course there is the full spectrum in between, For those of us nearer the perfectionist end of the spectrum, I offer the following: On the objects' menu right at the end is a section labelled "Extra". This is where the primitive shapes and the particle effects, as well as the cameras, sound sources, measuring tools, contact points and text boxes, can all be found. (I'm saying this for the benefit of anyone really new, who hasn't plucked up the courage to explore the "Extra" section yet...!) In the primitives' menu, you can find a variety of flat shapes and solid shapes. I've used these in the past to construct quite detailed buildings. But for this purpose, consider the flat rectangle "Ebene". Not particularly impressive? But position it right, just below the ground level (I use the1:1 scale track and baseboard, so it goes 5mm lower), size it correctly and colour it, and we get this: "Ah," I here the perfectionists say, "But you still have a gap there on the right!" Ah, yes. But this is where the box comes in A bit of fiddling with the edges of the embankment, and it all looks the way I want it to. The above pics were on a dummy layout. Here are a couple of examples from the layout I'm building: I hope this proves useful to at least one person... Cheers Simon

-

Passengers in the lift

Oh well. Thanks, Goetz. The B5 cars could do with having an engine added, and the B5 shafts with track, to save messing about with dummy track and dummy locomotives..., but it's doable as it is.

-

Passengers in the lift

Hi all. I'm trying to get passengers to go up and down with the elevator on the "Transition Elevator". I know it can be done with the B5 elevator car, because the car is a separate object so attaching the passengers to the car makes them move with it. But the "Transition Elevator" is all one unit, so attaching the passenger doesn't work! Am I missing something, or is this just not possible?

-

how to keep an eye on traffic lights in the distance or make them bigger?

Oh, right! Sorry. I didn't see the signals on the hidden loop! FB58B042-F0CE-4777-A155-491DC4303A2D - for a standard two-way point, 1E2DE4AE-FB18-4EB7-8CB7-D25015DD1B0E - for a three-way A76739BF-181C-4528-8A64-6E3204F85B96 - for a slip. They have options for different directions, you drop them onto the points on the control panel and connect them to the points on the layout. The button in the middle lets you manually change points on the layout from the control panel, and the yellow bar indicates the setting.

-

how to keep an eye on traffic lights in the distance or make them bigger?

The only thing I would say to that is that the occupied (red) sections of the control panel don't seem to be clearing properly, also the point indicators aren't set. Depending on how you have it set up, turning the red ones clear can be done with a simple event that has "When a vehicle leaves a track/street" as its activation, and sets the corresponding indicator on the control panel...

-

how to keep an eye on traffic lights in the distance or make them bigger?

I'm sort-of in agreement with @Phrontistes - You can put larger indicator lights that connect to the signals. Personally though I would put them on a control panel. The "Track Control Panel" system in its own section of the catalogue has signals that, if connected to the signal on the layout, will show the same aspect. Then position a camera to look at the panel and put it in its own window, and you can instantly see the aspect of any signal and also change them. You can even set this up to work with routes. I had an example of this that I lost when my PC died, but, oh well!

-

Turn the paintbrush to paint

To be honest, I find the faded circle brush is the best for river banks and track ballast. The fade provides a "uniform unevenness", even when painting on corners, that blends with whatever texture you put around it. What I would love to see is the ability to do the same with primitives...

-

Bahnübergang Halb-Schranke

This is probably a dumb question, but can you not just use the same animation to open and close the barriers by running it forwards and backwards?

-

Track allignment is slightly off

Using the "Model Oriented Standard Gauge" track, locate a Normal Straight at 0 x, 0 z, and all rotations at 0. (Y doesn't matter). Add a length of track to one end using the + tool. Keep doing this. After 10 or fifteen lengths, the x coordinate (which should remain the same) changes to -0.000. Odd, but not an issue. However, another fifteen or so lengths and the x coordinate is now -0.001. Only a millimetre at 1:1 scale, so not that important, right? Keep going, keep adding "straight" track, that is aligned to 0°. Soon enough, the discrepancy is 2mm. Then 3mm. Go far enough, and you will be a metre off ...! Okay, so this isn't supercritical and is easy enough to fix (if a massive pain in the proverbial). It does mean that catenary wires won't line up properly over long distances of "straight" track. But it is something that shouldn't happen. Clearly there is a rounding error somewhere in the code? I mean, it's not as if we're travelling interstellar distances, but with that sort of error over a distance of 1 light year, you'll miss your target by 27.5 million Km!

-

Another Signalling Question...

Sorry for asking this again, but... That can be interpreted two ways: 1) There can be a station entry signal that is not preceded by an advance signal (either separate or combined). 2) Station entry signals do not always have a KS2 aspect. I suspect that you mean option 2, because I cannot think of a circumstance where option 1 would be the case?

-

Another Signalling Question...

Thank you. Next question, which hopefully is as simple: The KS Main signal without the KS2 option, would be used when the block is longer than the required distance for an advance signal, and the separate KS Advance signal used at the required distance? Or does the KS Main have another use?

-

Another Signalling Question...

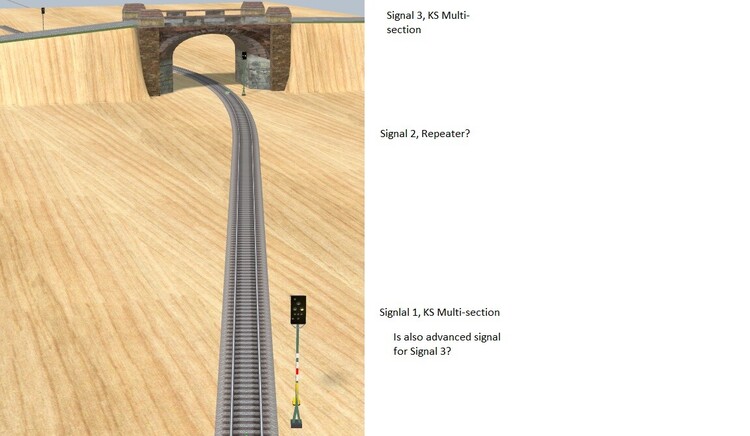

This is why I never publish completed layouts - They are never complete! I'm a perfectionist and I want things to be correct. To be clear, in the situation shown below: There is no separate "advanced signal" because the first signal functions as the "advanced signal" for the third one, so the second one is a repeater? And yes I'm one of those people who have to line up the catenary as exactly as possible. Cheers, Simon

-

Another Signalling Question...

Thanks, Goetz Right. So we have a KS Multiblock signal showing KS2 - Expect stop at the next signal. The next signal is 1km away and is showing HP0. In between the two is a bridge which obscures the driver's view of the next signal, so to give him warning of what it is showing now he's passed the Multiblock signal, we put a signal before the bridge. Is that an advance signal or a repeater? Rechts. Wir haben also ein KS-Multiblock-Signal mit der Anzeige KS2 – Stopp beim nächsten Signal erwarten. Das nächste Signal ist 1 km entfernt und zeigt HP0. Dazwischen befindet sich eine Brücke, die dem Fahrer die Sicht auf das nächste Signal versperrt. Um ihn also zu warnen, was dort angezeigt wird, nachdem er das Multiblock-Signal passiert hat, haben wir vor der Brücke ein Signal angebracht. Ist das ein Vorsignal oder ein Repeater?

-

Another Signalling Question...

Hi Guys... Please, will someone explain the difference between KS Advance and Repeater signals? So far as I can see, they both perform the same function. The multi-block signal shows the state of the next block signal, so any signal between the two is just repeating what the previous signal showed, Either KS1 or KS2. Also on a similar subject, which signal would you put at the entrance to station limits, KS Main or KS Multi-Block? If the latter, what is the former used for? Thanks Simon Hallo Leute... Kann mir bitte jemand den Unterschied zwischen KS Advance- und Repeater-Signalen erklären? Soweit ich sehen kann, erfüllen beide die gleiche Funktion. Das Multiblock-Signal zeigt den Status des nächsten Blocksignals an, sodass jedes Signal zwischen den beiden nur das wiederholt, was das vorherige Signal zeigte, entweder KS1 oder KS2. Und zu einem ähnlichen Thema: Welches Signal würden Sie am Eingang der Bahnhofsgrenzen anbringen, KS Main oder KS Multi-Block? Wenn letzteres der Fall ist, wofür wird ersteres verwendet? Danke Simon

-

Container Crane

A nice little demo. This transporter does have the disadvantage, that it won't pick up a container from another vehicle nor put down onto one. It can be used to move containers from a crane's unloading area to a storage area and back, which is something that a real port would need. ... That said, I often wonder what is inside the millions of containers that are sitting in port areas around the world...?

-

Error when vehicle with cockpit camera on dissapears in a depot

Yes, @Herman told me, and I have, thanks.

-

Error when vehicle with cockpit camera on dissapears in a depot

Added a new vehicle and it crashed again!

-

Error when vehicle with cockpit camera on dissapears in a depot

This has happened again. The red E-type Jag, going into an underground car-park that I'm kind-of cheating on, and rather than directing the cars to actual spaces Ihave them trip a track contact that pops them into a virtual depot that is currently invisible for aesthetic reasons. (I know it won't be visible in run mode, but I wanted to see the effect while in design mode!) Everything works fine, unless you are in cockpit view, and then it crashes without fail. Uploading the layout to Drafts, paused so if you unpause it, you will get the failure. Any idea when this will be fixed, or is it a V9 thing? Cheers Simon ====================================== Das ist wieder passiert. Der rote E-Type Jag fährt in eine Tiefgarage, die ich irgendwie betrüge, und anstatt die Autos in tatsächliche Räume zu lenken, lasse ich sie einen Gleiskontakt auslösen, der sie in ein virtuelles Depot bringt, das derzeit unsichtbar ist aus ästhetischen Gründen. (Ich weiß, dass es im Ausführungsmodus nicht sichtbar ist, aber ich wollte den Effekt im Designmodus sehen!) Alles funktioniert einwandfrei, es sei denn, Sie befinden sich in der Cockpit-Ansicht, und dann stürzt es zwangsläufig ab. Das Hochladen des Layouts in „Entwürfe“ wurde angehalten. Wenn Sie also die Pause aufheben, wird der Fehler angezeigt. Irgendeine Idee, wann das behoben wird, oder handelt es sich um eine V9-Sache? Prost Simon =========== 0007A822-3C2D-4D8C-A33B-65B42C9540A5 Aaaand it didn't crash... It did every time before I uploaded it, and the uploaded version didn't!

-

3-Way Catenary.

Hi, me again! I have a little problem, that I may have solved, but I'm wondering if there might be a better solution? A three-way point, with overhead electrification catenary. The standard boom will do single (default), long, short, and two varieties of double with long and short in opposite orders. But there is no "triple". At first I thought, use a double for the two outer tracks and have the wire for the central track go straight through to a seperate boom and mast. but that mast then gets in the way of the tensioner mast when I want to end the catenary on that side. Plus it looks messy. I also tried the transverse hangers, but the one on the same side as the middle one overlaps it. What I eventually came up with is this: A single boom sat right in the middle of a double boom. It works, and it looks neat. I just wonder if there is a better way, or if I stumbled onto the correct way, because the single boom fits exactly between the two arms of the double boom, which makes me wonder if t was designed like that? Incidentally, I also found that track flicker can be reduced to almost nothing my lowering the angled track on a junction by 0.001 (or 1mm at 1:1 scale, which is well within the tolerance of a prototype wheel!) This can also be done on everything else that flickers, except for pre-made models that have a built-in flicker!

-

New : Portal connection via EV ( new beta update )

Lua is something I am learning slowly and piecemeal. As with any programming language, the trick lies in knowing what goes where, and what you can and can't do with a function, operation, and property, as well as knowing what of the aforementioned building blocks are available! When I was in my 20s I learned a version of COBOL for my work, and there was a massive book in the office with all the various non-standard functions that could be called to do different things. In my 30s I tried to learn Delphi, and in my 40s, Visual C++. I mastered the syntax and the basic principles of both languages easily. What I didn't have was that book with all the available function calls and what they did! I might see if I can find a book on Lua, because it would be handy to know it. But yes, I can see that function, could easily be modified from a standard Event "When Switch Position Changes"... Thanks. If I ever find myself needing it, I will have totally forgotten this post!

-

Unloading wagons

There's probably a way to do it using the iteration "for all vehicles in a train", but I suspect that would require 10 calls to a user-defined event and some very careful timing to get the delay right for each wagon! The contacts are easier!

-

Unloading wagons

Fair enough. Thanks as always! I've got it working with a single track contact and a single wagon with four chutes, now to copy everything 9 times and see if it works. Going to back up the layout first!, just in case!

-

Unloading wagons

A train of hopper waggons comes up a slope, moving slowly. As it reaches the top it passes across a bridge with a receiving bin underneath. The locomotive moves on, and the first waggon comes onto the bridge. As soon as it is fully on, a mechanism opens the dump chutes on the waggon and the content pours out into the hopper. By the time the waggon is about to exit the bridge it is empty. The mechanism closes the chutes and as the train continues to move the waggon is replaced by the one behind it. So I have a "waterfall" particle effect attached to each chute of the waggon. There are ten waggons in the train. I could do this with ten track contacts, each of which holds a list of particle effect objects to be activated, and set a delay to deactivate them, but it feels clumsy to have the locomotive trigger the same event ten times. What I would prefer would be for the waggon itself to trigger the event when it is fully over the receiving hopper, have the list of P.E.s on the waggon, and save ten extra objects on the layout (because the event could be triggered by the waggon leaving the track before). But I can't see a way to access the individual waggons within a train in that way. Is there a way to achieve this, or will I just have to use ten track contacts?

-

New : Portal connection via EV ( new beta update )

I know, but if the junction wasn't there, I'd just connect the two signals together, set the advance signal to "Do Nothing" on the route it's actually in, and leave it at that.